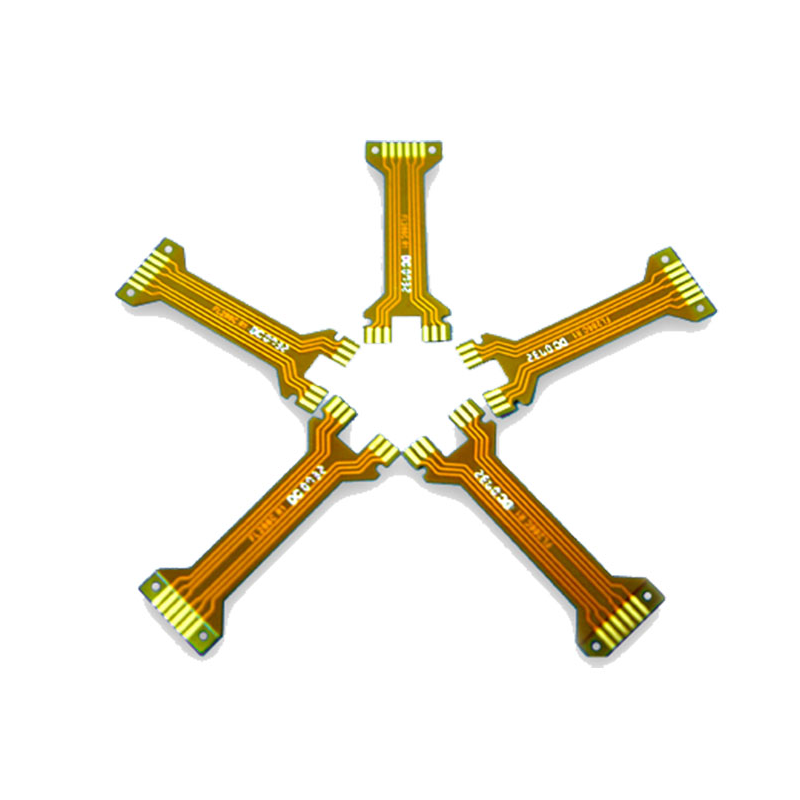

SIENTA: FPC Immersion Gold vs Plated Gold: What’s the Difference?

Wanna know the little secrets behind the processes of immersion gold boards and plated gold boards? Come on, let’s uncover them together!

① The immersion gold board is like a magician, using magical chemical reactions to conjure up a layer of gold-glinting coating. This is the unique skill of the chemical nickel-gold deposition method!

② And the plated gold board? It’s like an electrical powerhouse, harnessing the power of electrolysis and electric current to clad itself in a golden armor. That’s the charm of the electroplating method!

In the actual battlefield, immersion gold boards occupy the throne of most gold boards! Because plated gold boards have a serious flaw: poor welding performance, which is a real pain!

So, what are the benefits of immersion gold boards? Don’t worry, I’ll tell you all about it!

⑴ The golden appearance of immersion gold boards is even more dazzling than plated gold, which has a slight whitish hue (due to the nickel color).

⑵ Immersion gold boards are pros at welding, and they won’t give you any trouble or cause welding defects. Absolutely no issues!

⑶ Immersion gold boards are picky—they only appear on the pads. This way, the solder mask and copper layer on the circuit can hold each other tightly, without any disputes during engineering compensation!

⑷ Nowadays, wiring is getting more and more precise. We Sienta can even handle a minimum line-to-line spacing and width of 2 mils! Plated gold, however, can easily cause gold wire shorts. But immersion gold boards only have gold on the pads, so gold wire shorts? Not a chance!

⑸ Compared to plated gold, the crystal structure of immersion gold is super dense and resistant to oxidation. And the flatness of immersion gold boards is top-notch, making them a pleasure to look at!

How about that? Now do you have a deeper understanding of immersion gold boards and plated gold boards?